FOD Prevention Mats Deployed at NASA's Kennedy Space Center

Kennedy Space Center

Merritt Island, Florida

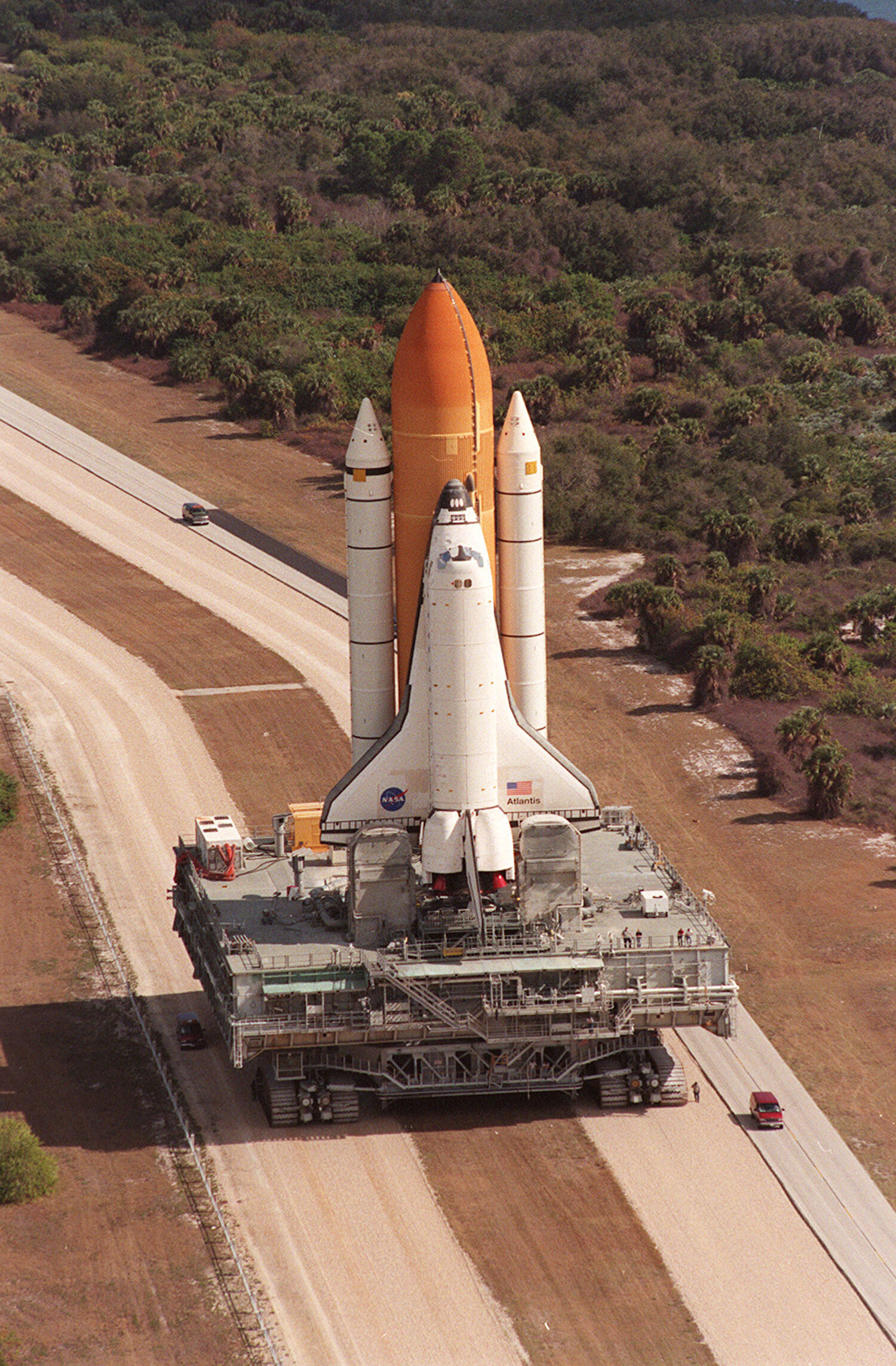

NASA’s Kennedy Space Center (KSC) has a rich history of launching space exploration missions which have reached unexplored worlds and proved that the sky is not the limit. KSC includes unique facilities, equipment and structures designed to allow assembly and transport of the massive rockets and payloads to the launch site. The two main launch complexes on Merritt Island, Launch Complex 39 A and B, have continued to be used by the National Aeronautics and Space Administration since the 1960s when they were built to launch the Saturn V rocket and spacecraft modules during the Apollo missions.

The Apollo Missions required the construction of specialized buildings and equipment including the Vertical Assembly Building (VAB), the Transport Crawlers, and the Mobile Service Structure. The VAB is where the multi-stage rockets and the spacecraft payloads are assembled and prepared for launch. Once assembled, the rockets must be transported to the launch site. The fully assembled rocket and spacecraft module can exceed a staggering 363’, about 60’ higher than the Statue of Liberty, and weigh over 6 million pounds (2.8m kg). In 1965, NASA built a pair of Crawler-Transporters to move the Saturn V rocket and Command and Service Module (CSM). Each of the Crawlers are the size of a baseball infield and weigh over 6 million pounds and currently hold the record for largest self-powered land vehicle in the world. After the rocket is placed on the launch pad, the 10.49-million-pound Mobile Service Structure (MSS) was transported to the launch site to allow technicians to attach umbilical connections to the pad and complete final inspections. The buildings, crawlers and support structures have continued to be used and serviced for over 50 years since their debut.

November 2021 is the projected launch date of the next generation Artemis missions. The Artemis Missions will continue to push space exploration to new heights culminating in a human mission to mars. To prepare for the next generation missions, the Kennedy Space Center is implementing improvements to their facilities and equipment. NASA has upgraded the Crawlers and is renovating areas of the Crawlerway to transport the new rockets, called Space Launch System (SLS), which will have a larger payload capacity than any previous rocket.

The dual road route, called the Crawlerway, was built to support the massive weight of the Crawler, the fueled rocket, and spacecraft modules. Composed of two 40’ wide lanes separated by a 50’ median, the routes to LC39A and LC39B stretch 3.4 miles and 4.2 miles, respectively. The top layer of the lanes consists of spark-resistant Tennessee River Rock which is up to 8” in depth. Below the River Rock, there is 6.5’ of gravel and fill that is designed to help support the weight of the Crawler. Renovations are underway to upgrade and repair the Crawlerway and facilities which includes the removal of a building that was used to store the decommissioned Mobile Service Structure (MSS). These Crawlerway improvements will ensure that the SLS and other commercial missions can be safely transported to the LC-39 launchpads.

Frank-Linn Excavating was contracted to complete the demolition and removal of the Mobile Service Structure holding building. To prevent tracking debris, sediment and other foreign objects into the Saturn Causeway, FOD Prevention Mats were installed at the entrance of the construction area. The contractor had installed FOD Prevention mats on the Saturn Causeway in a temporary application the demolition phase of the work. Because the mats are easily relocated, the system provides a solution for FOD Control that can be repurposed for the task at hand, or installed permanently on an active roadway.

The system works by deforming tires as vehicles pass over the pyramids on the tops of the mats releasing debris trapped in tire treads. Foreign Object Debris (FOD) and sediment falls to the base of the pyramids away from subsequent vehicle tires. This modern, reusable system can be deployed in as little as 30 minutes over asphalt, concrete, or soil. Being a rockless system, the composite mats provide a solution for sensitive areas where introducing rocks poses a safety or environmental risk. As operators work towards a FOD Free environment, contractors using FOD Prevention Mats can reduce foreign debris from vehicle tires that enters high FOD risk areas.

Special thanks to Eric Smith with Ferguson Waterworks for supplying the FOD Prevention Mats for this application.

FOD Prevention Mats installed to keep debris off the paved access roads.

FOD Prevention Mats are easily transported, configured, installed, removed, and relocated to reduce FOD tracked from vehicle tires onto access roads and aircraft intersections. FOD Prevention Mats contain rows of alternating pyramids that are engineered to separate tire treads and dislodge debris. Sediment and debris collect at the base of the pyramids away from vehicle tires. The FOD Prevention Mat System can help to reduce foreign object debris (FOD) that is tracked onto active taxiways. FOD Prevention Mats can also contain sediment and debris that may be contaminated with PFAS or other hazardous substances.

FODS Mats can withstand weights in excess of 80 tons per mat, and are made from a durable polyethylene which make FODS easy to transport, move, relocate, and reuse. FODS include a 15 year UV inhibitor enabling applications on both short term projects and permanent installations.

FOD Prevention Mats are 100% made and sourced in the USA and can be completely recycled at the end of their 15 year lifecycle.

Originally designed as a reusable stabilized construction entrance, the effective design of the mats allows a wider application as is seen in the case of the Chennault International Airport. The mats can also be used to contain trackout from airport construction projects. The effective and low maintenance solution can contain debris without introducing rock or aggregate to the airfield.

Contact FODS today for more information.

844-200-3637

info@getfods.com.